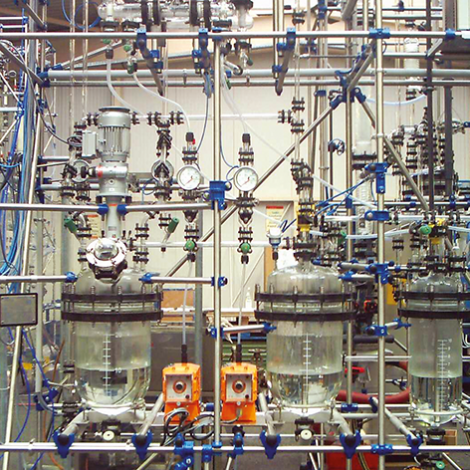

Experimental Hall

Experimental Hall

In the Department of Process Engineering of De Dietrich Process Systems all process-relevant questions are addressed from the customer inquiry to internal planning consultation up to commissioning of the plant at the customer. Approved simulation software and design programs are used for this. But exactly the influence of pollution or by-products during distillation or the effects of surface-active substances during the extraction an exact pre-calculation can often not be sufficiently made. In this case experiments are essential. In addition they also make offering process guarantees possible.

Individual process steps can be tested in the test facility if it is not possible to fall back on De Dietrich Process Systems know-how for new products or processes.

Test facility for your processes

The test facility is used to develop company-own components and processes as well as for testing and optimizing customer-specific tasks. Also the production of small amounts is possible. Safe design bases are created specially through a combination of computer-supported simulation and feedback from experiments.

Columns of up to 10 m are possible in the two-storey building. Due to the QVF modular glass system unit operations can be adapted quickly and flexibly to the task.

.

.

These processes can be tested:

- One or multi-stage concentration of contaminated sulfuric acid

- Cleaning and concentration of mineral acids such as hydrochloric and nitric acid

- Rectification of all mixtures common in the chemical and pharmaceutical industries

- Strip and desorb (e.g. chlorinated hydrocarbons from waste water)

- Recovery of high-boiling organic material from water via extraction (e.g. phenol, acetic acid)

- Energy-saving waste water concentration via mechanical vapor compression

- Batch distillation and reaction

Excerpt from the list of equipment:

- Horizontal boiler

- Thin film evaporators 0.05 and 0.2 m²

-

Rectification and stripping columns DN50 to DN150

with random or structured packing - Mixer settlers DN80 and DN100

-

Extraction columns DN50 to DN100

(pulsed sieve tray and packed columns, oscillating disc columns, stirred columns -

Glass lined reaction vessels

50 liters and 100 liters - Measurement data logging and registration

Rental systems:

- Mixer settlers DN80 and DN100

- Thin film evaporators

- Almost all unit operations from the thermal separation technique can be expanded at your request.

Energies:

- Heating steam of up to 10 bar

- Thermal oil of up to 210°C

- Cooling water

- Brine up to - 15°C

- Vacuum

.

Experimental Hall, De Dietrich Process Systems GmbH

Schoßbergstraße 11

65201 Wiesbaden, Germany

50.04554, 8.20823